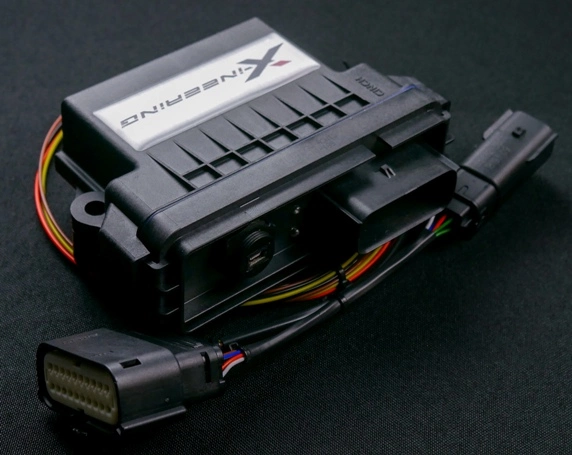

GCU - Gearbox Control Unit

Clutchless Shifts - Spark Cut & DBW Blip - Closed Loop

USB Programmable

Paddleshift details coming soon

Features

- Dedicated Hi-Current Ignition Coil Power Circuit (12Vin/12Vout)

- Load cell signal input hardware filtered (dampens noise spikes, false cuts)

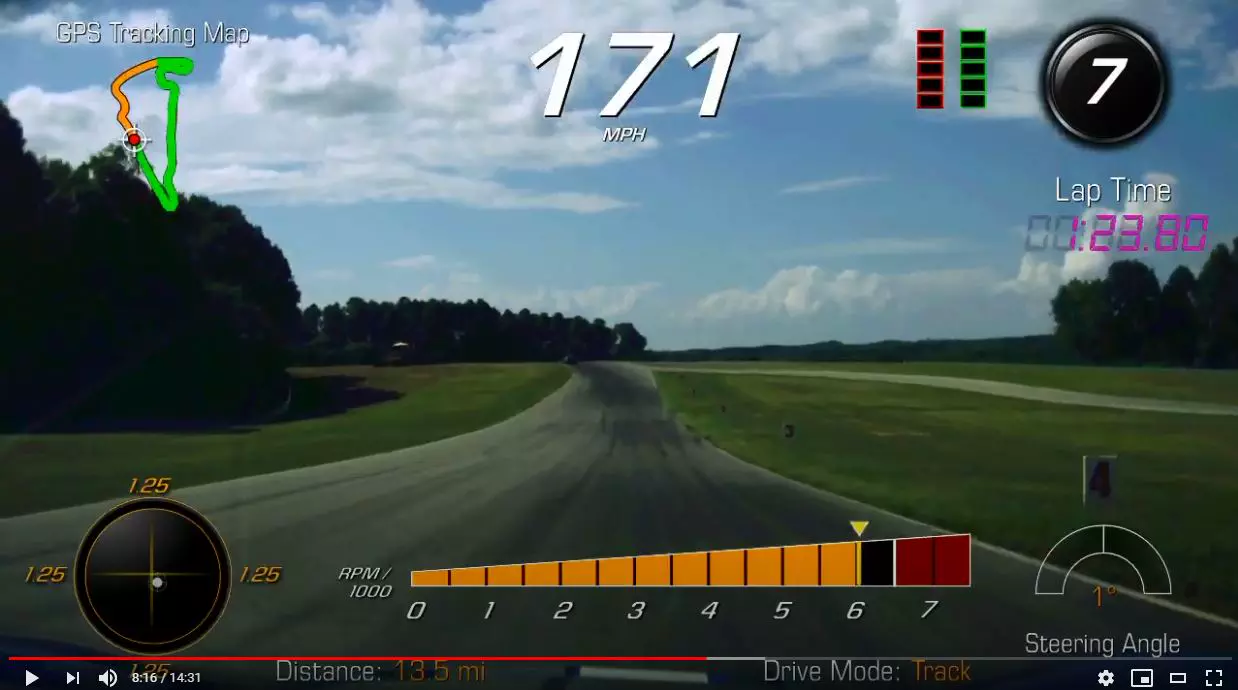

- Close loop shift timing strategy based on gear position sensor data, ignition cut/blip durations dependant on ACTUAL shift time from one gear to the next.

- Torque Recovery, ramp-in ignition power to the coils post-shift for ultra smooth operation.

- Preloaded with track tested base calibration to get you started.

System Description

Our GCU is an essential addition to any sequential transmission setup. An accurate torque reduction during up-shifts at WOT and throttle blip on down-shifts under braking is required to obtain the most efficient operation out of your sequential transmission.

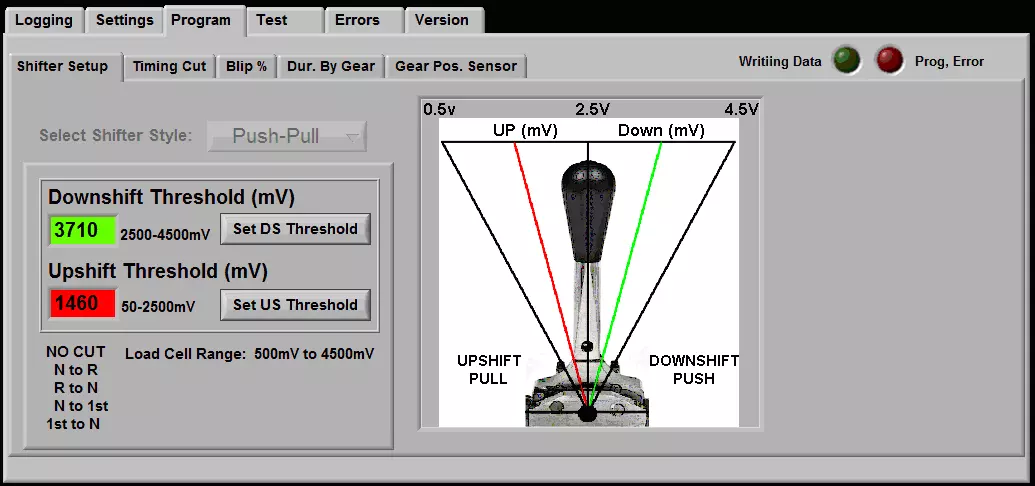

Dog-ring engagement is dependent on a torque reduction (synchronized with the shift level) to perform a smooth accurate shift. Torque reduction is performed by cutting power by a specified % (and duration, 0 to 500ms) to the ignition coils during a shift event. The shift event is initiated by a load cell shift knob (Push or Pull) or steering wheel paddle switches.

This allows for clutchless WOT (no-lift) shifting on upshifts, as well as clutchless (rev-matched) downshifts.

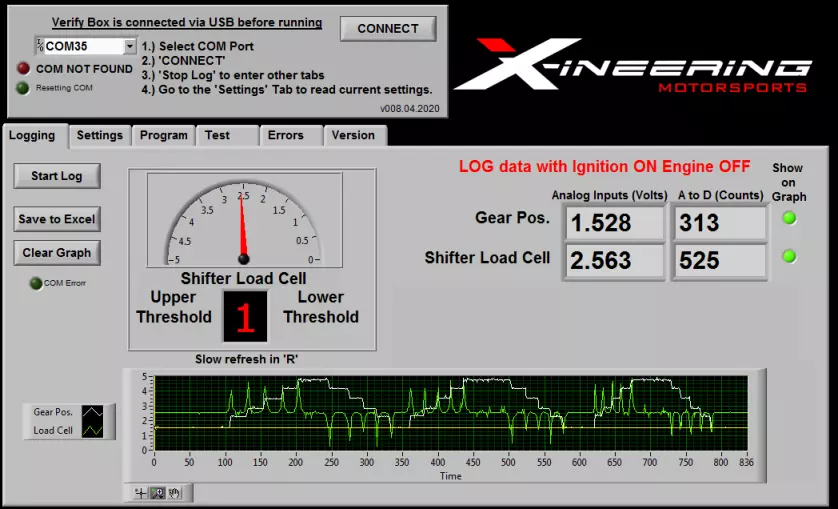

The duration of the cut/blip is programmable in Open-Loop (static durations) OR Closed-Loop based on the gear position sensor action.

Post Shift Ignition Ramp In period (ms), there is a torque recovery period, after the shift is complete, that ramps the spark back to 100% linearly.

Xineering's GCU Software provides the race engineer the ability to cut the ignition coil power by a given duration and/or percent based on the gear the transmission is shifting into. (When the transmission is equipped with a gear position sensor.)

Also See: DBW Standalone Throttle Blip Modules for H-pattern cars

Sensor Inputs:

- Load Cell Shift Knob (Push-Pull) or (H-pattern)

- Gear Position Sensor (optional)

- Steering wheel switches from Paddle Shift system (optional)

Adjustable Parameters:

- Downshift Load Cell Threshold (mV)

- Upshift Load Cell Threshold (mV)

- Ignition Cut %

- Throttle Blip Target % (for downshifts)

- Table: Calibrate Gear Position Sensor (Gear Pos. vs. Volts)

- Table: Shift duration by gear (ms)

- Table: Upshift duration (ms) vs. Gear

- Table: Downshift duration (ms) vs. Gear

- Table: Torque Recovery Period Up/Downshift duration (ms) vs. Gear

- Delay after Thres. (ms)

- Minimum Time between shifts (ms) - Buffer to prevent double cut